Ideal for High Speed Planters / Variable Rate Side Dressing

When it comes to todays high speed planters, the AgXcel GX30 VRT solution completely addresses the wider range of application requirements. Going from 3MPH to 12 MPH is one thing, but maintaining consistent liquid fertilizer system pressure is quite the other. The GX30 completely manages operational pressure which increases application accuracy and a greater range of flow rates.

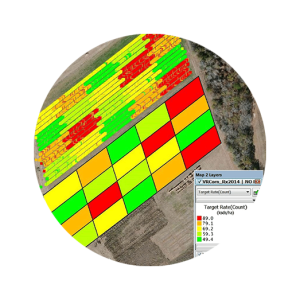

Prescription Based Application

Your prescription based application fields are no longer limited. With the AgXcel GX30VRT you can now apply variable rate the way it was designed to be applied. Whether its planting, 2×2, side dressing or spraying the GX30 will allow you to set it and forget it!

Application Rate Changes on the Fly

The AgXcel GX30 allows you to manage the required field GPA rate on the fly. When conditions or decisions change between fields, the GX30 can be changed on the fly at any time. When one field required 5GPA and then another field required 6.2 GPA you can apply with confidence using the GX30 solution.

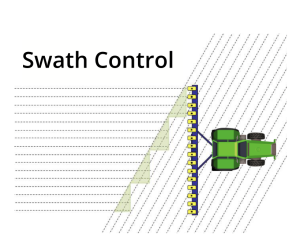

Swath Control

The GX30 has the ability to be configured for swath control electronically. Setup swath according to your requirements. No longer are you stuck to one configuration. Each row has the ability to become a section, all depending on your field requirements.

The AgXcel GX30i is your high-speed planter solution, designed to enhance efficiency and accuracy in liquid fertilizer application. This intelligent microprocessor manages and controls system pressure in a Variable Rate application environment, accommodating a wide range of application rates.

Key Features:

1. Intelligent Decision Making: The GX30i utilizes a sophisticated microprocessor to dynamically manage system pressure, ensuring optimal application across varying rates.

2. Dual Valve Management: This configuration, controlled by the central microprocessor, maintains system pressure within a specified range, adapting to the demands of different application rates.

3. Broad Application Range: Unlike traditional systems limited by orifice size, the GX30i can handle application rates spanning from 20 GPA to 40 GPA. This flexibility allows for precise, prescription-based applications without compromising system performance.

Benefits:

– Enhanced Efficiency: By managing pressure intelligently, the GX30i ensures consistent and accurate application, reducing waste and optimizing resource use.

– Versatility: The dual valve system and broad range capability allow for use in various field conditions and crop requirements.

– Improved Yield: Accurate and efficient fertilizer application promotes better crop health and yield, making the GX30i an invaluable tool for modern agriculture.

Designed and developed by AgXcel, this solution represents the forefront of liquid fertilizer application technology, providing farmers with the tools they need to maximize productivity and sustainability in their operations.

The AgXcel GX30iVRT offers advanced features for managing liquid fertilizer application rates with ease and precision. Here’s how it enhances your agricultural operations:

Key Features:

1. Dual Micro Control Valves: Utilizes two dual micro control valves per row, allowing seamless shifting between micro metering tubes to maintain optimal system pressure.

2. OEM Agnostic Compatibility: Can operate independently of your current setup and is compatible with various agricultural equipment brands.

3. CANBUS Control: Uses CANBUS technology to control each row individually, eliminating the need to manually check valves on each row.

Benefits:

– Stable System Pressure: The dual micro valve setup ensures stable liquid system pressure, promoting greater application accuracy and reducing wear on pumps typically caused by high pressure.

– Enhanced Efficiency: Enables quicker application startup at the beginning of each pass, optimizing operational efficiency in the field.

– Precision Application: Maintains precise application rates across varying conditions, enhancing crop health and yield potential.

The GX30iVRT from AgXcel integrates advanced technology to streamline liquid fertilizer application, offering farmers a reliable solution to manage rates effectively while improving overall operational performance.

The AgXcel GX30 Variable Rate Technology comes in 2 models. The GX30VRT that supports swath control, and the GX30Lite version when swath control is not required.

GX30Lite

The GX30iLite from AgXcel offers a cost-effective solution for farmers who require simplicity and effectiveness in their liquid fertilizer application processes, particularly for side dressing requirements.

Key Features:

1. Intelligent Pressure Monitoring: The GX30iLite is equipped with an intelligent pressure monitoring system. Users can set high and low-pressure thresholds through simple adjustments, ensuring optimal performance without the need for complex settings.

2. Flexible Application Support: Supports various application rates (GPA) and speeds (MPH) for side dressing needs, providing flexibility in agricultural operations.

3. Mounting Options: Can be easily mounted on the tool-bar of the implement using the provided mounting holes on the module. Alternatively, it can be secured using Velcro for quick attachment and detachment.

Benefits:

– Cost-Effective: Provides a budget-friendly option for farmers who do not require swath control features but still need reliable pressure monitoring and adjustment capabilities.

– Simple Setup: Easy installation and setup process, allowing farmers to adjust pressure thresholds through straightforward adjustments, minimizing setup time and maximizing efficiency.

– Enhanced Efficiency: Optimizes fertilizer application by ensuring pressure remains within specified thresholds, thereby improving application accuracy and reducing operational inefficiencies.

The GX30iLite module is designed to meet the needs of farmers looking for a straightforward yet efficient solution for managing liquid fertilizer application in side dressing operations.

The AgXcel GX30iVRT benefits:

The AgXcel GX30iVRT addresses this issue with the ability to broaden this range by implementing a 3 stage orifice range system. Exhaustive testing at AgXcel has established the critical benefits of a 3 option orifice system.

- A 3 system orifice setup with our Dual Body micro valve setup allows for a much broader range of application both at higher rates and at lower rates.

- 2 orifice sizes are selected, one for the lower and one for the upper range.

- The 3rd orifice is created by allowing both micro valves to open which combines the lower and upper range into a dual application ratio, allowing for a much broader range.

- AgXcel also uses our GX6 micro tubing technology to size the application range with 11 different sizes, for solutions that are viscous or have high particle content.

- The micro valve controls the flow on each row and creates an instant “shut off” point therefore preventing system pressure loss when the liquid system goes into hold mode.

- Systems today use check valves to prevent “drain out” when the system goes into hold. System pressure will drop down to the check valve pressure setting. So if you have 8lb check valves, system pressure will drop down to approximately 8 psi if not lower.

- With the micro valves system, pressure is maintained when the valve is shut.

- This pressure maintaining feature results in a quicker application start when the system goes back into start mode. The liquid system does not have to build pressure back to it delivering rate which in turn causes start points not to have fertilizer placement until enough pressure is in the system to open up the check valves.

- Lower GPA rates are also achieved at lower PSI ratings. Since there is no longer a check valve that has to open after system pressure is built, with the micro valves they are either flowing or not flowing. This means, even if system pressure reduces down to 2PSI, liquid will still be flowing at the appropriate rate since no pressure is required to open a rated check valve.

- The dual micro valves now serve as the liquid systems “sectional valves” therefore, there no longer is the need to run exhaustive amounts of 3/4” feed hose thoughout the implement.

- Implementing the dual micro valves on each row allows for a more responsive application when the system goes from hold position to run.

The AgXcel GX30iVRT intelligent module has an array of intelligence built into the system and designed to manage various pressure points seamlessly. With its ability to control each valve independently swath control is improved by allowing instant flow when the system returns to the flow position. With the ability to manage each row independently and up to 12 sections the GX30iVRT has been developed for expandability for future swath and row management. Additionally, AgXcel has 2 versions of the GX30iVRT, one version is the GX30iVRT-L that is a light version that does not have swath control features for those customers who have smaller implements or do not require swath control. The second version of the GX30iVRT is a full feature set system.

How does the AgXcel GX30 Variable Rate Technology work?

AgXcel’s GX30iVRT technology works by intelligently managing dual metering tubes that are located at the end of each row unit for the precise flow of liquid to each row. Because the GX30iVRT uses dual micro control valves on each row, all management of precise liquid application happens at the end of each row, and not throughout your implement where leaks could drip all over.

The utilization of dual micro control valves provides the technology to automatically shift between metering tubes to maintain and manage optimal system pressure. The GX30iVRT is OEM agnostic and can run independently of your current setup or can be integrated into your OEM CANBUS system and be controlled from the VT in your current cab monitor. With the state-of-the-art dual micro valve setup on each row using CANBUS to control each row, you no longer have the need to check valves on each row. Which in turn keeps your liquid system pressure stable. The stabilization of pressure then promotes GREATER application accuracy, reduces wear on your pump that high pressure causes, and allows for quicker application startup at the beginning of each pass!

Explore Products

- Request your hassle free quote now!

- AgXcel YouTube

- Order by Phone: +1 (877) 218-1981